If you’re a jeweller, metal workshop, or gold lab in Dubai, choosing the right annealing furnace can be the difference between high-quality results and costly mistakes. With so many options available, how do you pick one that’s right for your needs?

In this complete guide, we’ll break down everything you need to know before buying an annealing furnace for gold. Whether you’re upgrading your old system or buying for the first time, this guide will help you make an informed decision.

What Is an Annealing Furnace for Gold and Why Is It Important?

An annealing furnace is used to heat and soften gold after it’s been cast, shaped, or rolled. This heat treatment:

- Removes internal stress

- Improves ductility and workability

- Enhances final finish and quality

- Reduces breakage during further shaping or polishing.

Why It Matters in the UAE?

UAE’s jewellery industry is booming, and quality consistency is non-negotiable. From Karama workshops to luxury brands in DMCC, artisans need a reliable heat treatment process.

Choosing the right annealing furnace ensures:

- Better finish & purity in gold items

- Uniform heating and temperature control

- Enhanced workplace safety

- Longer life of gold-processing equipment

Key Factors to Consider Before Buying

1. Gold Quantity You Process

- Small workshops: Go for a smaller size

- Mid-scale operations: Choose bigger furnaces

- Labs & assay centres: Look for furnaces with precise controls

2. Heating Technology

- Electric Resistance Furnaces (popular): Simple, reliable

- Gas-Fired Furnaces: Rare, less common in Dubai due to safety concerns

✅ Pro Tip: For consistent annealing, go for programmable models with digital temperature controllers.

3. Temperature Range

- Ideal range for gold annealing: 600°C – 900°C

- Make sure the furnace supports accurate ramp-up and cooldown

4. Chamber Material

- Go for high-alumina fibre insulation or ceramic muffle for long-lasting performance

5. Space & Power Availability

- Compact designs are best for Dubai’s space-limited workshops

- Choose models that run on single-phase 230V if you’re in a small unit

6. Safety Features

- Overheat protection

- Insulated exterior

- Fume outlet or compatibility with scrubbers/fume hoods

In the UAE’s competitive jewellery and assay market, precision and consistency are everything—your furnace must deliver both.

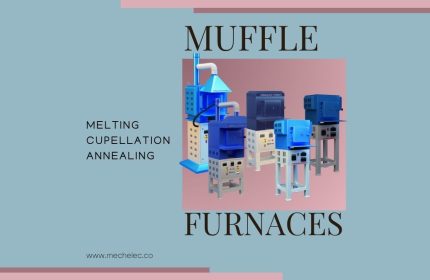

Mechelec’s Annealing Furnaces

We offer compact, energy-efficient annealing furnaces ideal for local jewellers, refiners, and labs.

| Mechelec’s Annealing Furnace Large | SPECIFICATIONS | Mechelec’s Annealing Furnace Small |

| Front Loading | Furnace Type | Front Loading |

| 900°C | Max Temperature | 900°C |

| W 260mm x H 200mm x D 290mm | Muffle Size | L 150mm x H 125mm x D 300mm |

| Silicon Carbide Heating Element | Heating Elements | Silicon Carbide Heating Element |

| 6 Nos. | Number of Elements | 4 Nos. |

| 3 KW | Rated Power (Max) | 2.2 KW |

| Three Phase | Rated Input Voltage | 220 Volt AC |

| 20 Minutes | Heat-up Time | 10 Minutes |

| L 610mm x W 600mm x H 1500mm | Size | L 570mm x W 500mm x H 1250mm |

| 90 kg | Weight | 60 kg |

Why Mechelec’s Annealing Furnaces are the best for the UAE?

- Compact design – Ideal for small and large-scale users

- Fast heat-up time – High-output demands during peak seasons

- CE-certified components – Compliance with UAE safety regulations

- Local support & warranty – Quick replacements, no import delays

Final Thoughts: Invest Smart for Long-Term Gains

Buying the right annealing furnace isn’t just about price; it’s about reliability, safety, and performance. If you’re based in the UAE, choosing a locally supported brand like Mechelec can save you time, money, and headaches.

Not just locally, our furnaces are trusted in the UAE and shipped worldwide.

Don’t settle for trial-and-error. Get it right the first time.

Click here to explore our wide range of products.