Gold melting using induction heating is the preferred choice for jewellery manufacturers, bullion refiners, assay laboratories, and precious metal recyclers. The process offers speed, cleanliness, and precise temperature control – but it also generates intense heat that must be managed carefully.

For B2B operations where uptime, accuracy, and equipment protection directly affect profitability, an industrial chiller is not an accessory—it is a critical system component.

This article explains why chillers are essential specifically for gold melting induction furnaces, what risks arise without proper cooling, and how the right cooling solution supports consistent, high-value production.

Who This Is For

This guide is intended for:

- Jewellery manufacturing units

- Gold bullion and refining facilities

- Assay and fire assay laboratories

- Precious metal recycling plants

- Furnace manufacturers and system integrators

If your operation relies on induction furnaces for gold melting, cooling reliability directly impacts product quality, equipment life, and operating cost.

Heat Generation in Gold Melting Induction Furnaces

Gold melts at approximately 1064°C, but induction furnaces operate at much higher internal temperatures due to:

- High-frequency alternating currents

- Strong electromagnetic fields

- Continuous or repeated melting cycles

Significant heat is generated not only in the molten metal but also in:

- Induction coils

- Power electronics (IGBTs, capacitors, transformers)

- Bus bars and power cables

- Crucible holders and furnace structures

Without stable cooling, this heat accumulation can quickly affect system performance and reliability.

The Role of Chillers in Gold Melting Applications

An industrial chiller is a closed-loop cooling system that circulates temperature-controlled water (or water–glycol mixtures) through the induction furnace and its power supply.

In gold melting systems, chillers are engineered to:

- Maintain a constant outlet temperature

- Handle high thermal loads during continuous operation

- Protect sensitive electrical and mechanical components

Compared to tap water or open-loop cooling, chillers offer controlled, clean, and repeatable cooling, which is essential in precious metal processing environments.

Why Gold Melting Induction Systems Require Chillers

1. Protection of High-Value Power Electronics

Induction gold melting furnaces rely on advanced power electronics operating within strict temperature limits. Inadequate cooling can result in:

- IGBT and capacitor failure

- Power instability during melting

- Sudden furnace shutdowns

A properly sized chiller keeps electronics within safe operating limits, ensuring reliable and uninterrupted melting cycles.

(Learn more about Mechelec industrial chillers engineered for induction furnace power supplies.)

2. Continuous Cooling of Induction Coils

Induction coils are subjected to extreme thermal and electromagnetic stress. Without controlled cooling:

- Copper coils may soften or deform

- Coil insulation can degrade

- Heating efficiency drops over time

Chillers provide continuous, stable cooling that preserves coil geometry and maintains consistent melting performance.

(Explore Mechelec closed-loop cooling solutions for induction coils.)

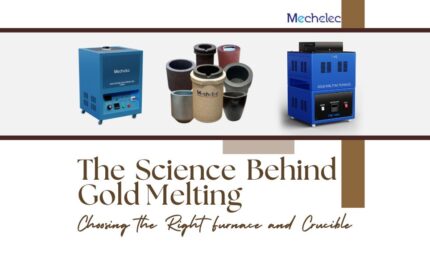

3. Accurate Temperature Control for Gold Quality

Gold melting requires precise thermal control to:

- Prevent metal loss due to overheating

- Avoid crucible damage

- Maintain purity and consistency of the melt

Unstable cooling conditions can affect furnace behavior. Chillers deliver repeatable thermal stability, supporting accurate and predictable melting results.

4. Extended Crucible and Furnace Life

Gold melting crucibles—especially graphite crucibles—are high-value consumables. Poor cooling can:

- Increase thermal shock

- Accelerate crucible wear

- Cause premature cracking or failure

By controlling surrounding temperatures, chillers reduce thermal stress and extend crucible and furnace service life.

(See Mechelec-compatible cooling systems designed for gold melting furnaces.)

5. Support for Continuous and Batch Operations

Jewellery workshops and refineries often operate furnaces across multiple shifts. Industrial chillers are designed for:

- Continuous duty cycles

- Stable performance under peak thermal loads

- Reliable operation in industrial environments

This makes them essential for high-throughput gold melting operations.

6. Elimination of Water Quality Issues

Tap water or open-loop cooling introduces risks such as:

- Scale formation inside coils

- Corrosion of internal passages

- Flow blockages and inconsistent cooling

Closed-loop chillers use filtered or deionized water, significantly reducing maintenance requirements and protecting critical furnace components.

7. Improved Energy Efficiency and Cost Control

When induction furnaces operate within optimal temperature ranges:

- Electrical losses are minimized

- Power transfer efficiency improves

- Energy consumption per melt is reduced

For gold melting operations, this translates into lower operating costs and improved process efficiency.

What Happens Without a Chiller?

Operating a gold melting induction furnace without proper cooling can lead to:

- Unstable melting temperatures

- Frequent alarms and unplanned shutdowns

- Coil and power supply damage

- Reduced gold recovery efficiency

- High repair costs and production downtime

In precious metal processing, even minor equipment failures can result in significant financial loss.

Selecting the Right Chiller for Gold Melting Furnaces

When choosing a chiller for gold melting induction systems, key considerations include:

- Cooling capacity matched to furnace power (kW)

- Stable outlet temperature control

- Adequate flow rate and pressure

- Compatibility with clean or deionized water

- Ambient operating conditions

Selecting a chiller engineered for induction applications ensures safe, precise, and uninterrupted gold melting operations.

(View Mechelec induction furnace chillers designed for gold melting applications.)

Conclusion

For gold melting induction systems, chillers are mission-critical. They protect high-value electronics, preserve induction coils, extend crucible life, and ensure stable melting conditions.

In B2B environments where precision, uptime, and cost control are essential, the right chiller directly supports product quality, operational efficiency, and long-term reliability.

At Mechelec, we design and supply industrial chillers specifically engineered for gold melting induction furnaces. Our solutions are selected based on furnace power, duty cycle, and operating environment—supporting jewellery manufacturers, refineries, and assay laboratories with cooling systems built for performance and reliability.

(Learn more about our Gold Melting Furnaces and more products.)

Frequently Asked Questions (FAQs)

Gold melting induction furnaces generate extreme heat in coils and power electronics. A chiller removes excess heat, prevents overheating, and ensures stable and safe furnace operation.

Tap water cooling can cause scale buildup, corrosion, and inconsistent cooling. Industrial chillers provide controlled, closed-loop cooling that protects high-value furnace components.

Chiller sizing depends on furnace power (kW), duty cycle, operating frequency, and ambient conditions. A properly sized chiller ensures stable temperature control and long equipment life.

Insufficient cooling can lead to coil deformation, power supply failure, unstable melting temperatures, crucible damage, and costly downtime.

Yes. Even small-capacity gold melting furnaces require stable cooling to protect electronics and ensure consistent melting quality.