When researching fire assay equipment, you might come across two terms: cupellation furnace and cupel furnace. At first glance, they may sound like two different machines, leading to confusion for buyers and students of metallurgy alike. In reality, both terms refer to the same type of furnace – a specialised high-temperature unit designed to carry out the cupellation process for testing and refining precious metals like gold and silver.

So why do two names exist? The answer lies in the difference between cupellation (the refining process) and the cupel (the small, porous vessel used during the process). Over time, the industry began using both terms interchangeably. In this article, we’ll clear up the confusion, explain the purpose of a cupellation (or cupel) furnace, and show why choosing a trusted supplier like Mechelec ensures accuracy, safety, and reliability in your fire assay operations.

Why the Confusion?

The confusion between “cupellation furnace” and “cupel furnace” comes from the way people refer to the process versus the equipment.

- Cupellation is the ancient and precise process of separating precious metals, like gold and silver, from base metals by heating them in a high-temperature furnace.

- A cupel is a small porous vessel that holds the metal during this process, allowing impurities to be absorbed into the material.

Over time, the furnace used to heat the cupels started being called both a “cupel furnace” and a “cupellation furnace.” In practice, they are one and the same machine. Whether someone searches for “cupellation furnace” or “cupel furnace,” they are looking for the same solution for accurate and efficient fire assay.

What is a Cupellation Furnace (aka Cupel Furnace)?

A cupellation furnace, also called a cupel furnace, is a high-temperature machine used to carry out the cupellation process. It separates precious metals like gold and silver from base metals by heating them in small porous vessels called cupels.

Key Features of a Cupellation Furnace:

- Precise Temperature Control: Maintains the high temperatures needed for accurate assays.

- Multi-Sample Capacity: Modern furnaces process multiple cupels at once, boosting lab productivity.

- Durable Design: Built to handle repeated high-temperature use.

- Safety Features: Protect users from heat and fumes.

Who Uses Cupellation Furnaces?

- Assay Labs: Conduct accurate precious metal analysis.

- Refineries: Ensure gold and silver reach the required purity.

- Mining Companies: Test ores for precious metal content.

- Educational Institutions: Teach students modern fire assay techniques.

At Mechelec, we design furnaces to meet labs’ and refineries’ needs. Our units deliver reliable performance, safety, and precise results. We offer both small-capacity and larger furnaces to match your operational requirements.

Discover how cupellation works and more about cupels—step by step.

How to Choose the Right Furnace for Your Lab?

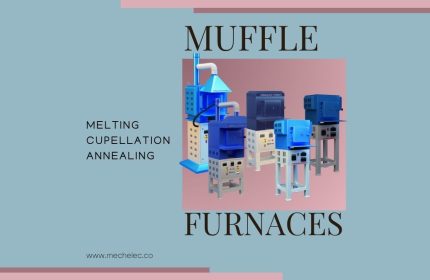

At Mechelec, we provide two types of cupel furnaces—each designed for different lab needs:

- SiC Muffle Furnace – Best for labs that require high durability, consistent temperature control, and longer furnace life. The silicon carbide muffle protects samples from direct flame contact, making it ideal for precise fire assay work.

- Open Muffle Furnace – A cost-effective option for labs with lower sample volumes or educational setups. Easier to operate and maintain, it offers good performance when ultra-high durability isn’t the top priority.

When deciding, consider:

- Sample Volume – Higher volumes benefit from SiC muffles for stability and lifespan.

- Temperature Precision – Both furnaces perform well, but SiC offers greater consistency.

- Budget & Use Case – Open muffle furnaces suit smaller labs or teaching purposes; SiC muffles are an investment for heavy-duty assay labs.

Our team at Mechelec can guide you in selecting the right furnace that balances performance, cost, and safety for your specific operation.

👉 “Need help deciding which furnace suits your lab? Contact Mechelec for expert advice.“

Why Choose Mechelec?

When labs invest in cupellation equipment, reliability matters as much as performance. Here’s what sets Mechelec apart:

- Proven Quality – Built with durable materials to withstand repeated high-temperature assays.

- Tailored Options – Choose between SiC muffle or open muffle furnaces, depending on your lab’s workload and budget.

- Global Reach – With presence in UAE and India, and international shipping available, we serve customers across Asia, GCC, Africa, and beyond.

- After-Sales Support – Our team provides guidance on installation, usage, and maintenance, ensuring long-term value.

- One-Stop Shop – Along with furnaces, we supply a full range of fire assay products (cupels, parting trays, fume scrubbers, and more).

By combining technical expertise with practical lab solutions, Mechelec helps assay labs run smoothly and efficiently.

Conclusion

Cupellation furnaces are essential for accurate fire assay testing, and choosing the right type can make a big difference in efficiency, cost, and results. Whether your lab needs the durability of a SiC muffle furnace or the simplicity of an open muffle model, Mechelec has you covered.

With our wide range of fire assay products, global shipping, and dedicated support, we’re here to help you build a reliable lab setup.

Whether you call it a cupel furnace or a cupellation furnace, Mechelec delivers reliable, lab-tested solutions worldwide. Contact us for a quote today.