In the world of precious metal refining, accuracy and purity mean everything—especially during fire assay, one of the oldest and most trusted methods for testing gold and silver content. At the heart of this process lies a small but powerful tool: the cupel.

But what exactly is a cupel, and why does it play such a vital role in assaying?

Let’s break it down.

What Is a Cupel?

A cupel is a small, porous ceramic container crafted primarily from bone ash or magnesium oxide. Refiners use it during the cupellation stage of fire assay to absorb lead and other base metals, leaving behind only precious metals like gold, silver, or platinum for analysis.

Its round, dish-like shape and heat resistance allow it to perform under the extreme conditions of the assay furnace. As a result, the cupel ensures reliable and precise assay outcomes.

What Is a Cupel Made Of?

Traditionally, manufacturers use bone ash (calcium phosphate) to make cupels. However, modern variations may also consist of magnesia (MgO) or cement-based materials.

To function correctly, a cupel must:

- Withstand temperatures of 900–1,050°C

- Remain chemically neutral

- Absorb oxides efficiently without affecting noble metals

These properties make the cupel an ideal tool for the demanding conditions of metal analysis.

Why Are Cupels So Effective?

Cupels are specifically designed to:

- Absorb lead oxide (litharge) during cupellation

- Resist thermal shock and cracking

- Provide a clean surface for forming and weighing the precious metal bead

Thanks to their porous structure, they allow the process to proceed cleanly and with high precision. That’s why they are indispensable in high-accuracy assays like the cupellation process.

Read more about the cupellation process.

How Cupels Are Used in Fire Assay

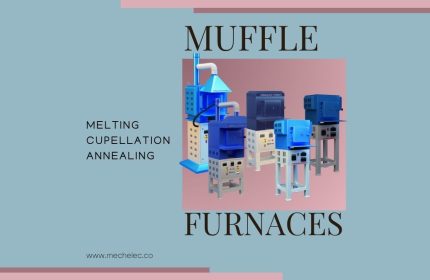

Fire assay involves multiple steps to separate precious metals from base components. Here’s how the cupel fits into the process:

- Preparation: First, a lead-based alloy containing the metal sample is placed in a furnace, along with the cupel.

- Cupellation: As the temperature exceeds 1,000°C, the lead oxidises and gets absorbed by the cupel’s porous walls. Learn the complete cupellation process used to separate precious metals.

- Isolation: Precious metals, which don’t oxidise, remain as a tiny bead on the cupel’s surface.

- Weighing: Finally, this bead is weighed and analysed to determine the exact gold or silver content.

Key Applications of Cupels in Gold and Silver Assay

Cupels are used in several critical scenarios:

1. Fire Assay of Gold and Silver

- As the most accurate method for testing metal purity, fire assay relies heavily on cupels.

2. Testing Precious Metal Content in Alloys

- Assayers use cupels to determine the gold or silver content in jewellery, coins, and ores.

3. Refinery Quality Control

- Gold and silver producers verify that their bars, coins, or ingots meet purity standards before sale or export.

4. Mining and Exploration

- During geological exploration, analysts assay rock and ore samples using cupels to gauge economic potential.

Industries That Use Cupels

Cupels are essential across a wide range of industries, including:

- Gold and silver refineries

- Jewelry manufacturing

- Mining and exploration companies

- Metallurgical research labs

- Government or private assay offices

Wherever precise purity analysis is required, cupels are there.

Choosing the Right Cupel

At Mechelec Thermal, we offer high-performance cupels designed for consistent results under extreme heat. Whether you’re working with small samples or large-scale batches, our cupels deliver:

- High absorption capacity

- Low ash content

- Superior thermal resistance

- Uniform porosity and density

Because we understand that precision matters, we’ve engineered our cupels to support your success in every assay.

Mechelec’s Tips for Proper Cupel Use

To maximize accuracy and maintain lab efficiency, follow these best practices:

- Preheat the cupel before introducing the molten sample.

- Always operate in an oxidizing furnace atmosphere for optimal lead oxide absorption.

- Use each cupel only once—they saturate after a single process.

- Store cupels in a dry, clean environment to prevent moisture absorption or contamination.

FAQs about Cupels

Q: Can a cupel be reused?

A: No. Cupels absorb metal oxides and should be used only once to maintain accuracy.

Q: What size cupel should I use?

A: It depends on the sample and furnace size…

Conclusion

The cupel may seem like a small, simple tool—but it plays a huge role in ensuring accuracy, purity, and consistency in gold and silver assays. Without it, the time-tested process of cupellation simply wouldn’t work.

Whether you’re a professional in a certified lab or an artisan refining gold, you can trust the cupel to deliver reliable results.

Explore our range of high-quality cupels and assaying equipment or visit the Products section of our website.

Have questions or need a custom solution? Contact us today — our team is here to help.