Fire assay has been trusted for centuries as the most reliable way to measure gold and silver content. Even in 2025, with XRF and spectrometry widely available, fire assay remains the benchmark for accuracy. But achieving precise results is not just about following the process — it depends heavily on the quality of equipment you use.

This guide takes a fresh, practical look at the essential fire assay equipment, what role each tool plays, and how to get consistent results every time.

Fire Assay in Simple Terms

Fire assay is essentially a three-step process:

- Fusion: The sample is mixed with flux and melted in a crucible until the precious metals are separated from impurities.

- Cupellation: Lead and base metals are absorbed by a cupel in a hot furnace, leaving behind a precious metal bead.

- Parting: Nitric acid dissolves silver, isolating pure gold for weighing.

Each step requires precision equipment to withstand extreme heat, chemical reactions, and repeated use without compromising accuracy.

Your Fire Assay Toolkit

1. Furnaces – The Heart of the Lab

The furnace is where most of the action happens in a fire assay lab. Choosing th

A reliable cupellation furnace provides:

- Even, stable heat across all samples

- Energy efficiency for daily use

- Digital temperature controls for repeatability

e right type of furnace ensures consistent, accurate results while keeping operations safe and efficient.

Explore how cupellation fits into the fire assay workflow for gold refining.

In addition to cupellation furnaces, other essential types include:

- Induction Melting Furnace: Used to melt batches of metals before assay. Ideal for high-volume operations, these furnaces maintain uniform temperature to prevent contamination or metal loss.

- Annealing Furnace: Helps relieve stress in metal samples and prepare them for accurate weighing or further processing.

A poorly calibrated furnace can ruin an entire batch, so regular maintenance is key.

2. Crucibles & Cupels – Small Tools, Big Impact

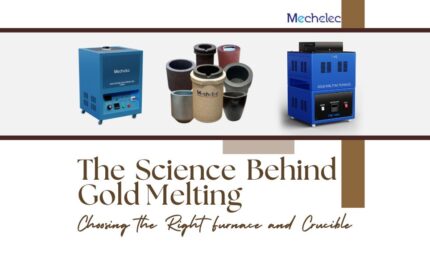

Even though they may seem simple, crucibles and cupels are critical to the accuracy of a fire assay. Choosing the right type and size can make a huge difference in results and safety.

Crucibles

Crucibles hold your sample during the fusion stage. Key considerations include:

- Variety of Types: There are different types of crucibles available, each designed to handle high temperatures and repeated use. The choice depends on your lab’s specific needs and sample size.

- Sizes: Crucibles come in various sizes, from small lab-scale batches to large industrial melts, starting from 500g to more.

Cupels

Cupels are used during cupellation to absorb lead oxide and separate precious metals from impurities. Choosing the right cupel is essential for a clean and accurate assay.

- Variety of Types: Different cupels are designed to optimize absorption and durability. Select the one that matches your workflow and sample requirements.

- Sizes: Cupels come in standard sizes suitable for different sample volumes. Choosing the correct size ensures proper absorption and consistent results.

💡 Pro Tip: Preheat crucibles and cupels before loading to avoid thermal shock.

Why It Matters

Using the wrong type or size of crucible or cupel can:

- Cause incomplete fusion or cupellation

- Lead to contamination or metal loss

- Introduce variability that undermines assay accuracy

Investing in high-quality crucibles and cupels, and matching them to your furnace type and batch size, ensures more reliable, repeatable results for every assay.

3. Muffles, Fluxes & Accessories

While furnaces, crucibles, and cupels are the stars of the fire assay, muffles, fluxes, and accessories play a crucial supporting role. They ensure your assay is safe, consistent, and accurate.

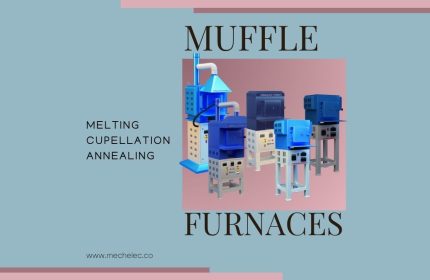

Muffles

A muffle is a chamber inside the furnace that provides controlled, uniform heat to your samples. It helps:

- Maintain consistent temperature across all samples

- Protect samples from direct flame or contamination

- Improve energy efficiency by keeping heat focused where it’s needed

Using a high-quality muffle ensures your fusion and cupellation steps are repeatable and reliable.

Fluxes

Fluxes are chemical mixtures added during fusion to separate precious metals from impurities.

- They help the molten charge flow evenly and reduce contamination.

- Consistent flux ratios are essential for reproducibility.

💡 Pro Tip: Keep your fluxes dry and store them properly — moisture can cause inconsistent fusion or spattering.

Accessories

A fully functional fire assay lab also depends on supporting tools and safety gear, such as:

- Tongs for crucibles, cupels, and parting trays

- Molds to cast metal beads

- Protective equipment like gloves, aprons, and face shields

- Measurement tools, stir rods, and thermocouples for monitoring temperature

Though these may seem minor, small accessories make a big difference in accuracy, safety, and efficiency. Skipping or cutting corners on accessories can lead to inconsistent results or lab accidents.

Best Practices for Reliable Assays

- Preheat Everything: Warm your crucibles, cupels, and furnace for consistent results.

- Keep Flux Ratios Consistent: Standardised recipes reduce variability.

- Log Every Run: Tracking inputs and outputs helps spot errors early.

- Schedule Maintenance: Calibrate furnaces and replace worn muffles regularly.

Why Proper Equipment Matters

High-quality equipment ensures:

- Accurate, repeatable results

- Reduced metal loss and contamination

- Compliance with industry standards

- Safer lab operations

Investing in the right tools today saves time, money, and headaches tomorrow.

Looking for Guidance?

Whether you’re running a small mining lab or a large refinery, choosing the right fire assay equipment is crucial for accuracy and efficiency. 📩 Talk to an expert at Mechelec today →