In every gold refinery or assay laboratory, precision is everything. From testing purity to forming gold bars, each step relies on controlled, consistent heat. That is exactly what a Muffle Furnaces provides.

A muffle furnace quietly supports gold assaying and refining. It delivers clean, uniform heat without direct flame contact, ensuring accuracy in key processes like Cupellation, Annealing, and Melting. Each step plays a vital role in transforming raw material into pure, high-quality gold.

At Mechelec, we design furnaces specifically for these demanding environments. They are reliable, efficient, and engineered for precision. Before choosing the right furnace, it helps to understand how these three core processes work together to achieve purity and perfection in gold refining.

The Role of Muffle Furnaces in Gold Assay

Every accurate gold purity test relies on one piece of equipment: The Muffle Furnace. It may not look dramatic, but it enables gold refiners and assay labs to achieve consistent, reliable results.

Unlike open-flame heating, a muffle furnace creates a clean, enclosed chamber. Samples heat evenly without touching fire or gases. This prevents contamination, which is critical in gold assaying, where even a tiny impurity can affect the results.

In simple terms, the muffle furnace gives technicians control over temperature, timing, and purity. Whether separating metals during Cupellation, relieving stress during Annealing, or preparing gold for Melting, precise heating makes each process work perfectly.

At Mechelec, we design every furnace for this precision. Our units maintain stable temperatures, reduce heat loss, and deliver consistent results, making them a trusted choice for gold refineries, testing labs, and research facilities.

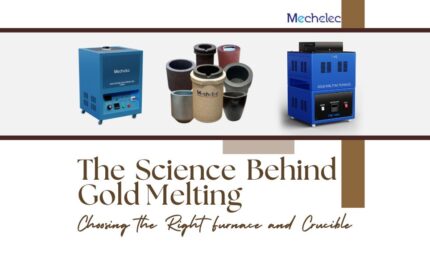

Melting Furnaces – The First Step Toward Refining Gold

Before gold can be tested, shaped, or transformed, it must melt. This is usually the first step in most refineries, and precision matters most here.

A Melting Furnace turns raw gold or scrap metal into a uniform molten state. This allows impurities to separate and makes the metal easier to refine or cast. The key is temperature control. Gold melts at about 1,064°C, and holding that exact range ensures a clean melt without metal loss or contamination.

A high-performance Muffle Furnace handles this with ease. Unlike open-flame heating, it delivers even, enclosed heat that reaches the target temperature quickly and holds it consistently. Labs achieve repeatable melting results, whether for small assay samples or full production batches.

At Mechelec, our melting furnaces combine accuracy and efficiency. They heat quickly, maintain stable conditions, and handle repeated cycles with minimal maintenance. The result? Smooth melting, reduced oxidation, and high-quality output every time.

Melting may seem simple, but it lays the foundation for accurate testing and the final gleaming bar of gold.

Cupellation Furnaces – Where Purity Begins

After melting, the next step is measuring purity. The Cupellation process and the Cupellation furnace make this possible.

Cupellation is one of the oldest methods for testing precious metal purity. A small gold alloy sample is heated in a porous cup (a cupel) at high temperatures. The heat oxidizes base metals like lead, copper, or zinc, which the cupel absorbs. This leaves a tiny bead of nearly pure gold or silver.

Temperature control is critical. The furnace must maintain steady, even heat without contaminating the sample. A few degrees off can affect results.

Mechelec’s Cupellation Furnaces focus on precision. Available in Silicon Carbide (SiC) and Open Type models, they deliver stable, uniform heat. The SiC type works well for quick, energy-efficient operations, while the Open Type provides easy access to handle multiple cupels during testing.

Cupellation is the moment of truth in every gold assay lab. A reliable furnace ensures accuracy, repeatability, and trust in the results.

Click here to know more about how Cupellation works.

Annealing Furnaces – Strengthening and Stress-Relieving Gold

After melting and testing, gold often needs conditioning. During melting and handling, metals can become hard, brittle, or stressed. This is where Annealing comes in.

Annealing softens gold, relieves internal stresses, and improves workability. Refiners heat the metal to a specific temperature, then cool it slowly. This process makes gold easier to shape, mold, or roll without cracking.

Temperature control is vital. Overheating can damage the gold, and underheating won’t relieve stress effectively. That’s why high-quality Annealing Furnaces are so important.

Mechelec offers small and large annealing furnaces for labs of all sizes. They provide consistent, even heat and allow technicians to control the process accurately. This ensures every batch of gold is ready for forming, testing, or casting.

In addition to annealing furnaces, labs often use melting furnaces for initial processing, cupellation furnaces for purity testing, and sampling trays and accessories for safe handling. Combining these tools ensures smooth workflows, reliable results, and high-quality gold output.

Annealing may not be as dramatic as melting or as exacting as cupellation, but it’s essential for durable, high-quality gold.

Click here to learn how to choose the right annealing furnace.

Frequently Asked Questions [FAQs]

A muffle furnace provides clean, uniform heat without direct flame contact. In gold assay labs, it’s used for processes like melting, cupellation, and annealing to ensure accurate purity testing.

Unlike open-flame heating, muffle furnaces maintain consistent, enclosed heat that prevents contamination. This ensures reliable, repeatable results — especially important when testing or refining precious metals.

A melting furnace liquefies gold for refining, a cupellation furnace tests purity by removing impurities, and an annealing furnace softens and stress-relieves gold for shaping or further use.

While some multi-use models exist, most labs prefer dedicated furnaces for each process — melting, cupellation, and annealing — to maintain accuracy, efficiency, and prevent cross-contamination.

Why Muffle Furnaces for Gold Assay Matter

From Melting to Cupellation to Annealing, every gold refining step depends on precision, consistency, and the right equipment. A Muffle Furnace is more than a tool. It’s the backbone of accuracy in every assay lab and refinery.

- Melting furnaces ensure gold reaches a uniform molten state, ready for refining and shaping.

- Cupellation furnaces reveal the true purity of metals, separating impurities with exacting heat control.

- Annealing furnaces soften and stress-relieve gold, preparing it for further processing or crafting.

At Mechelec, we offer a full range of high-performance furnaces and accessories for modern gold labs:

- Melting Furnaces for fast, consistent melting

- Cupellation Furnaces in SiC and Open types for accurate purity testing

- Small and Large Annealing Furnaces for stress-relieving and conditioning gold

- Sampling Trays and Accessories for safe handling and efficient workflow

Whether running a small assay lab or a large refinery, choosing the right furnace ensures precise results, smoother operations, and higher-quality gold.

Explore Mechelec’s range of products today and equip your lab with the tools trusted by professionals across the region. Contact us today.