Heating Elements

Available in different sizes and customizable to suit your furnaces

Interested in this product? Chat with our team on WhatsApp:

Description

Heating Elements – Reliable Heat Source for Industrial Furnaces

Mechelec Heating Elements provide the consistent, high-intensity heat required for demanding thermal processes. As the core of furnace performance, these industrial heating components ensure precision, efficiency, and durability in every application.

High-Performance Heat Generation

Manufactured from advanced, high-resistance alloys, the elements heat up rapidly and maintain stable temperatures throughout the furnace chamber. This uniform heating prevents hotspots and supports critical operations such as gold melting, metal refining, annealing, and material testing.

Built for Long-Term Reliability

Designed to withstand extreme operating conditions, these thermal elements resist oxidation, corrosion, and thermal fatigue. Even under continuous high-temperature use, they maintain performance with minimal degradation. This durability reduces replacement frequency, lowers maintenance costs, and improves overall productivity.

Easy Integration and Maintenance

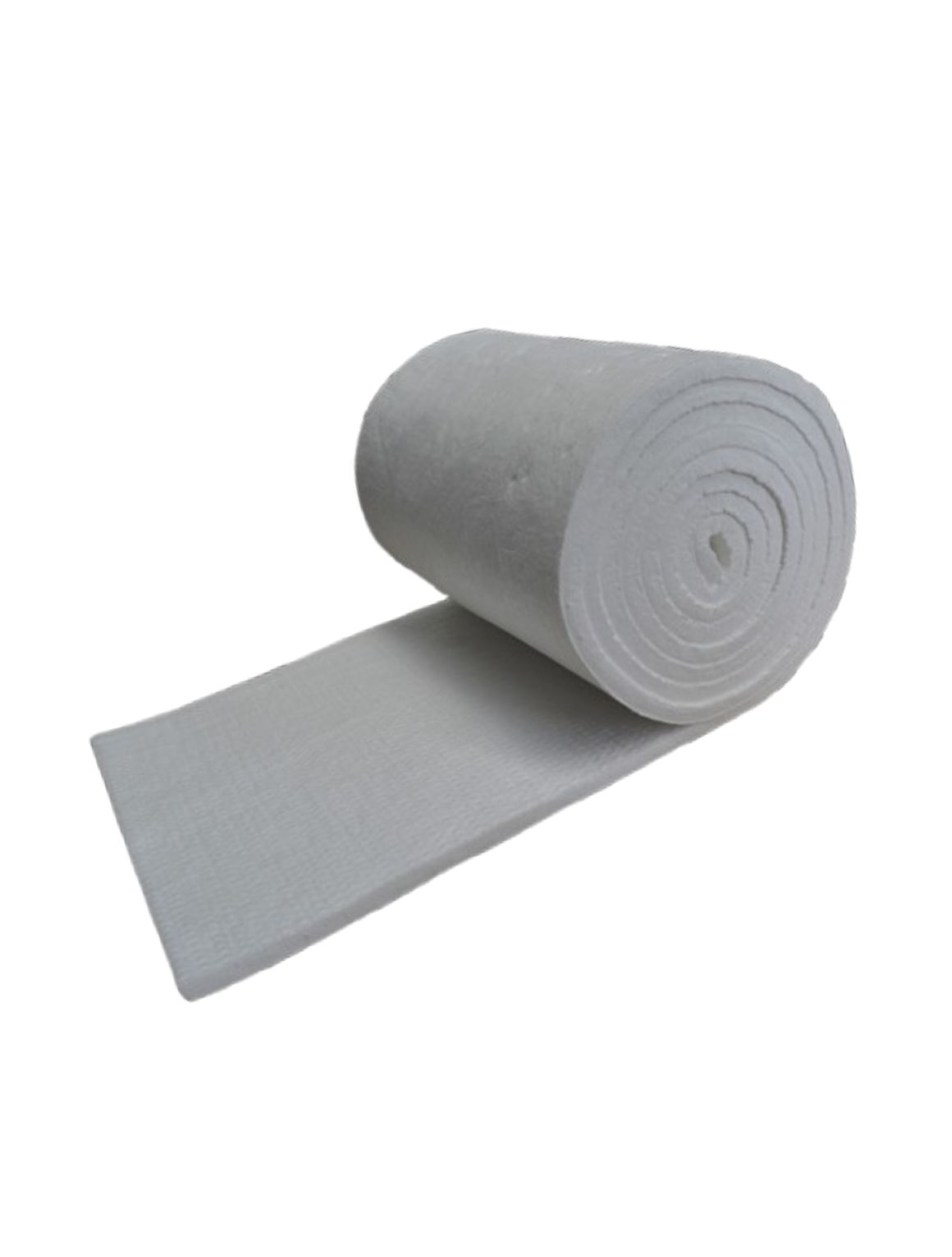

Compatible with most furnace designs, Mechelec’s electric furnace heaters connect securely to standard terminals for quick installation. Available in different sizes and customizable to suit your furnaces, they provide a perfect fit for both standard and specialized applications. Maintenance is straightforward — elements can be cleaned, inspected, or replaced with minimal downtime, keeping operations running smoothly.

Applications Across Industries

-

Fire assay and precious metal refining

-

Heat treatment of metals and alloys

-

Laboratory testing and material research

-

Industrial furnaces for production environments

Tested to International Standards

Every heating element undergoes rigorous quality testing to ensure safe and reliable operation in continuous use. Built to meet international industrial standards, they deliver consistent output with optimized energy efficiency.

Dependable Performance You Can Trust

Whether in production plants or research laboratories, Mechelec Heating Elements provide stable, even heating cycle after cycle. They are the dependable choice for reliable furnace operation and long-lasting thermal performance.

👉 Choose Mechelec heating solutions and keep your furnaces operating at peak efficiency. Contact us.

Interested in this product? Chat with our team on WhatsApp: