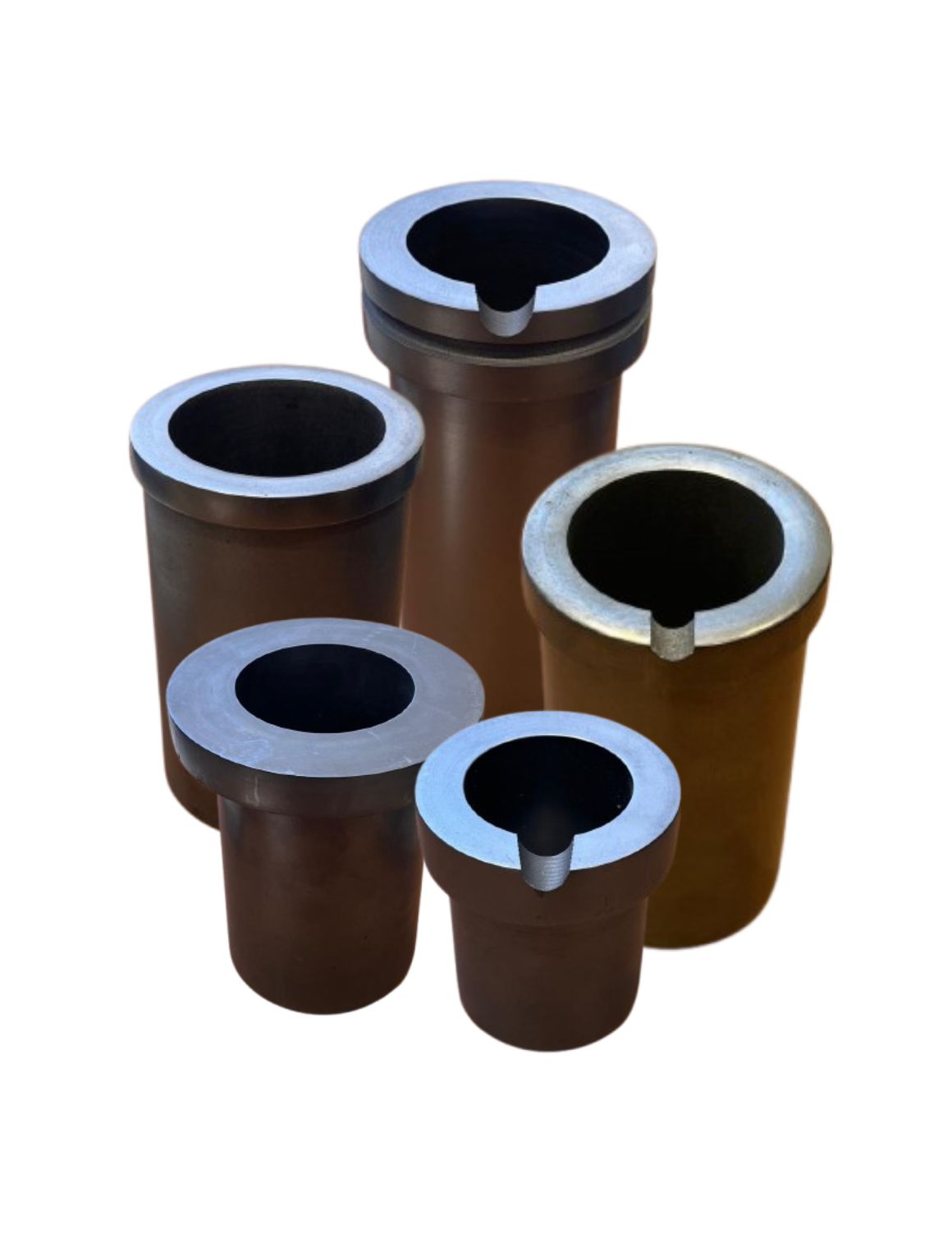

The Clay Graphite Crucible A10 delivers unmatched performance for large-scale metal melting operations. It handles extra-large batches of gold, silver, and other non-ferrous metals. If you run an industrial furnace or a high-output casting facility, this crucible is built for your workload.

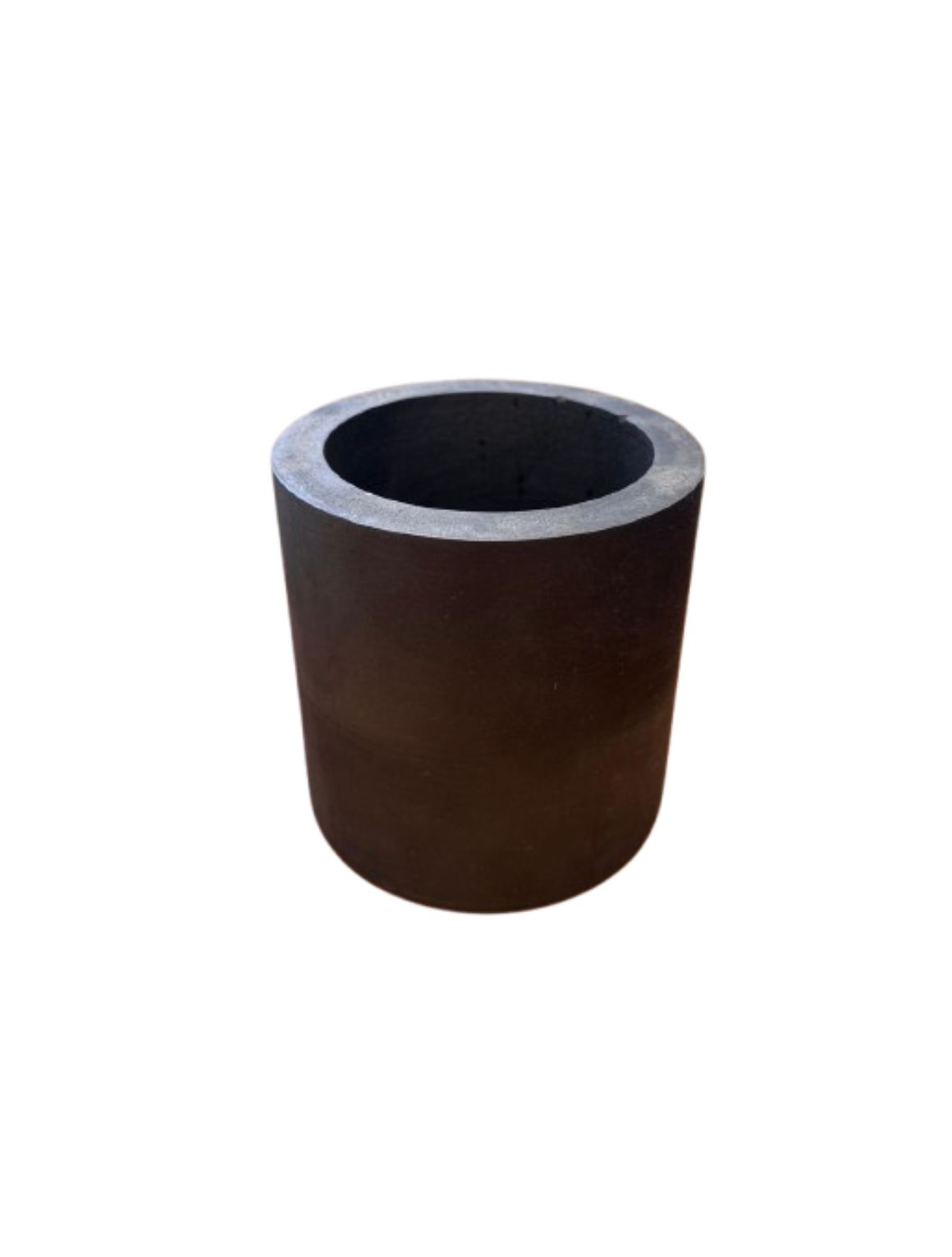

We engineer the A10 using high-purity graphite blended with top-quality refractory clay. This mix creates a crucible that resists extreme heat and sudden temperature shifts. It won’t crack or deform during rapid heating and cooling cycles.

Its large capacity means fewer melts are needed. You save time, reduce handling, and increase throughput. The crucible’s excellent thermal conductivity ensures fast and even melting from start to finish.

The interior surface is smooth, reducing metal residue and improving pouring accuracy. You get cleaner melts with less waste. It also resists chemical wear, oxidation, and mechanical stress, even under daily use.

The A10 stands firm under pressure. Its thick, reinforced walls hold up during heavy-duty cycles and high-temperature operations. You can use it confidently in induction, electric, or gas furnaces.

At Mechelec, we design tools that professionals trust. The Clay Graphite Crucible A10 is one of our most durable and efficient models. It performs flawlessly across a range of melting applications.

If you need a crucible that handles volume and lasts longer, choose the A10. It gives you the power to melt more, waste less, and work smarter every day.