Description

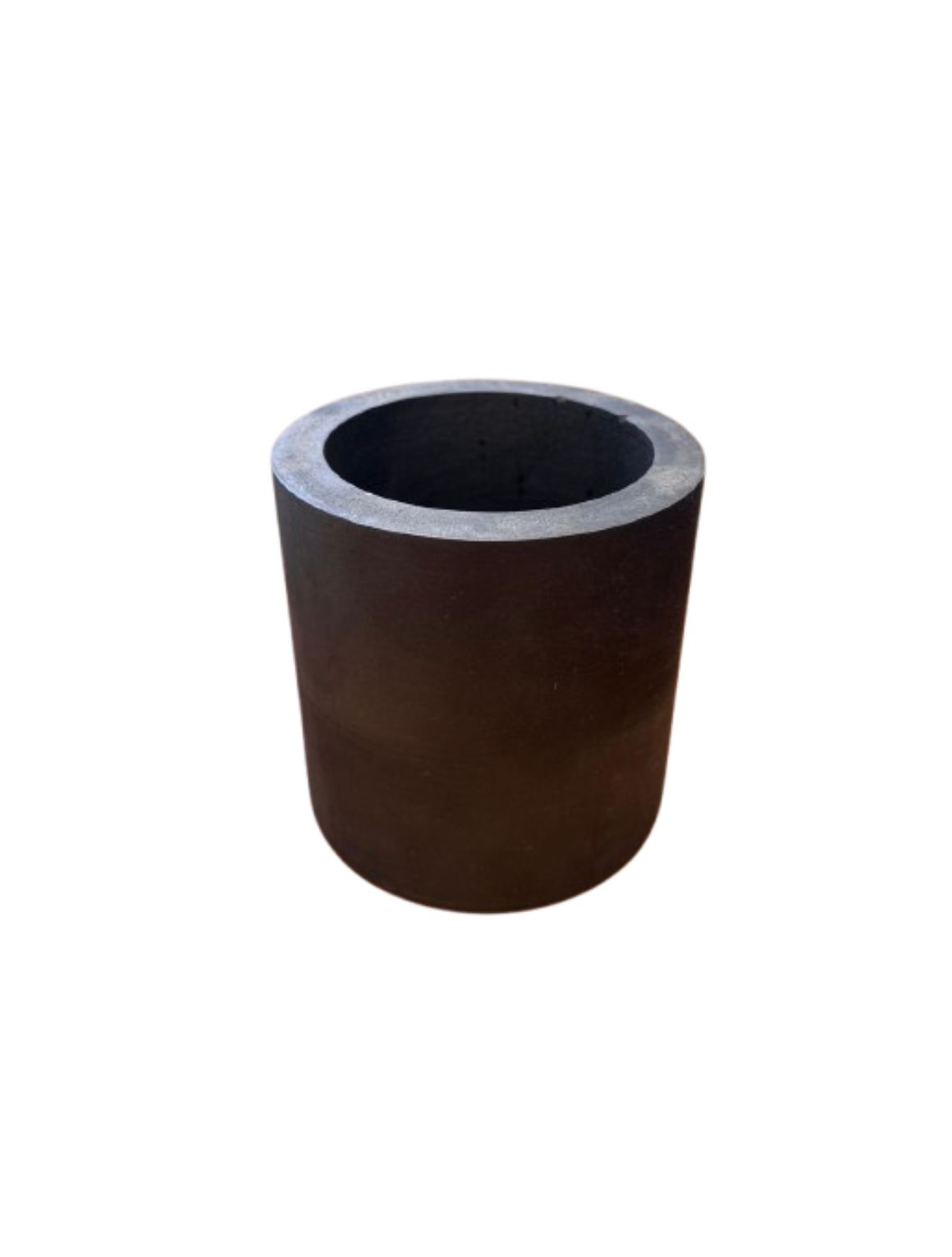

Customisable Grain Crucible for Metal Melting

Mechelec’s Customisable Grain Crucible is designed for high-precision melting and grain formation in gold, silver, and other precious metal refining applications. Whether you operate a small-scale lab or a large refinery, this crucible offers flexibility, durability, and performance you can count on.

What makes it unique? The ability to customize dimensions based on your furnace type, metal quantity, and output requirement. From casting beads to forming granules, you can select the grain crucible that matches your exact process. This reduces waste, improves metal control, and enhances furnace efficiency.

Crafted from high-density graphite, the crucible ensures even heat distribution. It resists thermal shock and withstands repeated heating cycles. That means fewer replacements, stable performance, and better overall cost-efficiency.

You can use this crucible in induction, gas, or electric furnaces. It works exceptionally well with grain-making attachments, letting you pour molten metal through filtered openings to form granules. This is a critical step in metal granulation, which aids in storage, blending, and reuse of gold or silver.

The crucible is easy to handle and safe to operate at high temperatures. Its customisable depth and wall thickness allow you to adjust the melting volume, improving batch control for different production sizes.

Order your Customisable Grain Crucible from Mechelec today and experience the precision that professionals rely on. Need help choosing the right configuration? Our support team is here to assist. Contact us now.