Description

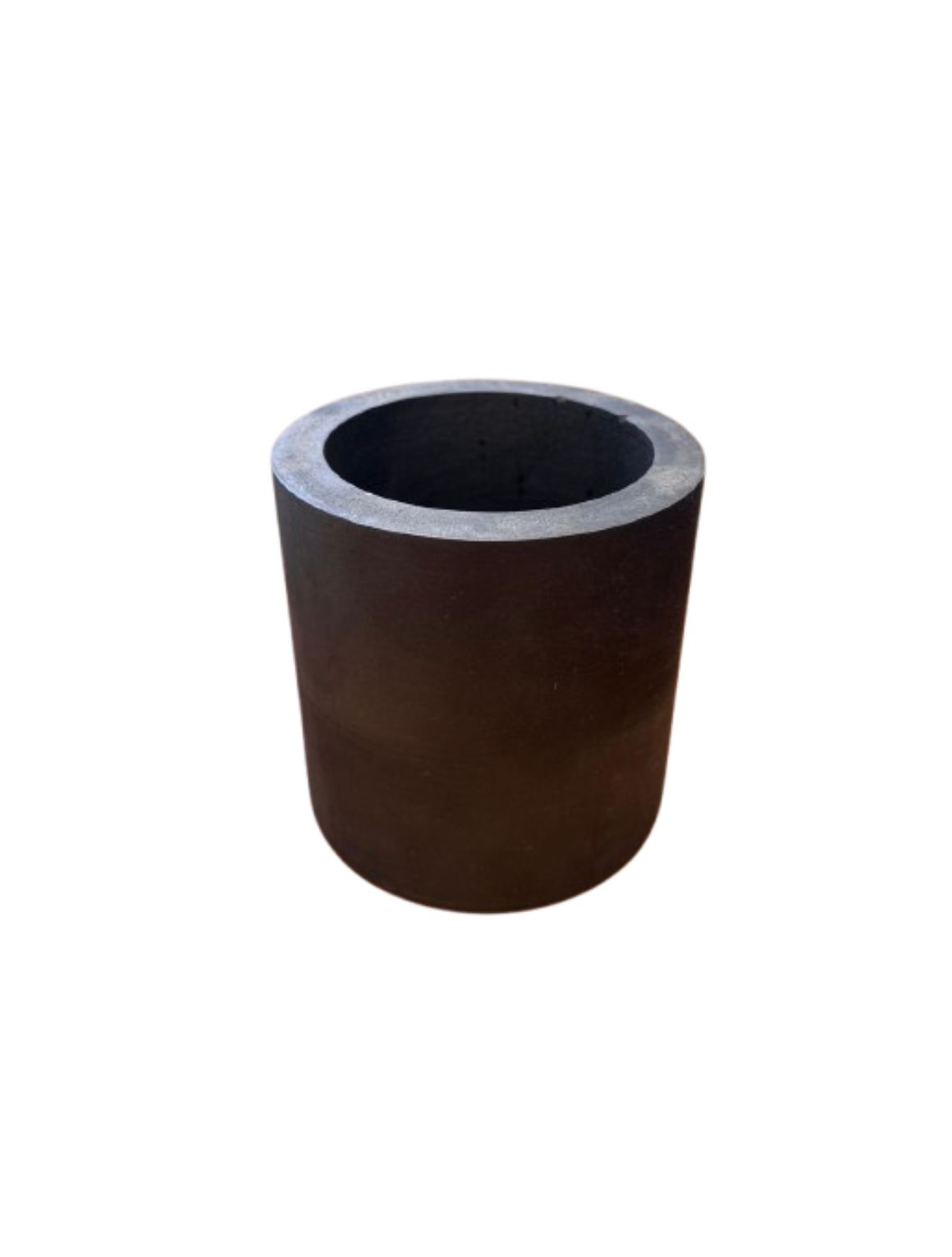

Casting Crucible for Precise Metal Pouring and Molding

Casting crucible play a vital role in metal shaping and refining. Designed for precision pouring, these crucibles help you cast molten metals into molds safely and accurately. They perform exceptionally well in gold, silver, copper, and alloy casting applications.

Mechelec offers casting crucibles made from high-quality refractory materials. We combine thermal strength with mechanical durability to ensure each crucible handles extreme heat and repeated use. You can count on consistent performance, batch after batch.

The crucibles resist cracking under thermal shock. This allows you to move from heating to pouring without delays or damage. Their smooth inner surface supports easy flow, reducing metal retention and waste. You get a cleaner pour every time.

We engineer each casting crucible to withstand high temperatures without deforming. Whether you’re using a torch, induction furnace, or gas setup, these crucibles remain stable and secure. They fit snugly into most melting systems and allow for steady handling during pouring.

You’ll find these crucibles essential in jewelry workshops, refineries, and small foundries. Their design simplifies the casting process. Pouring becomes more controlled, safer, and more accurate. That means less rework and better results.

At Mechelec, we focus on performance and quality. Our casting crucibles meet professional demands while staying affordable and long-lasting. From prototypes to production runs, they deliver the consistency metalworkers need.

Choose a Casting Crucible that works as hard as you do. Trust Mechelec to provide tools that support every stage of your casting workflow—efficient, clean, and built to last.