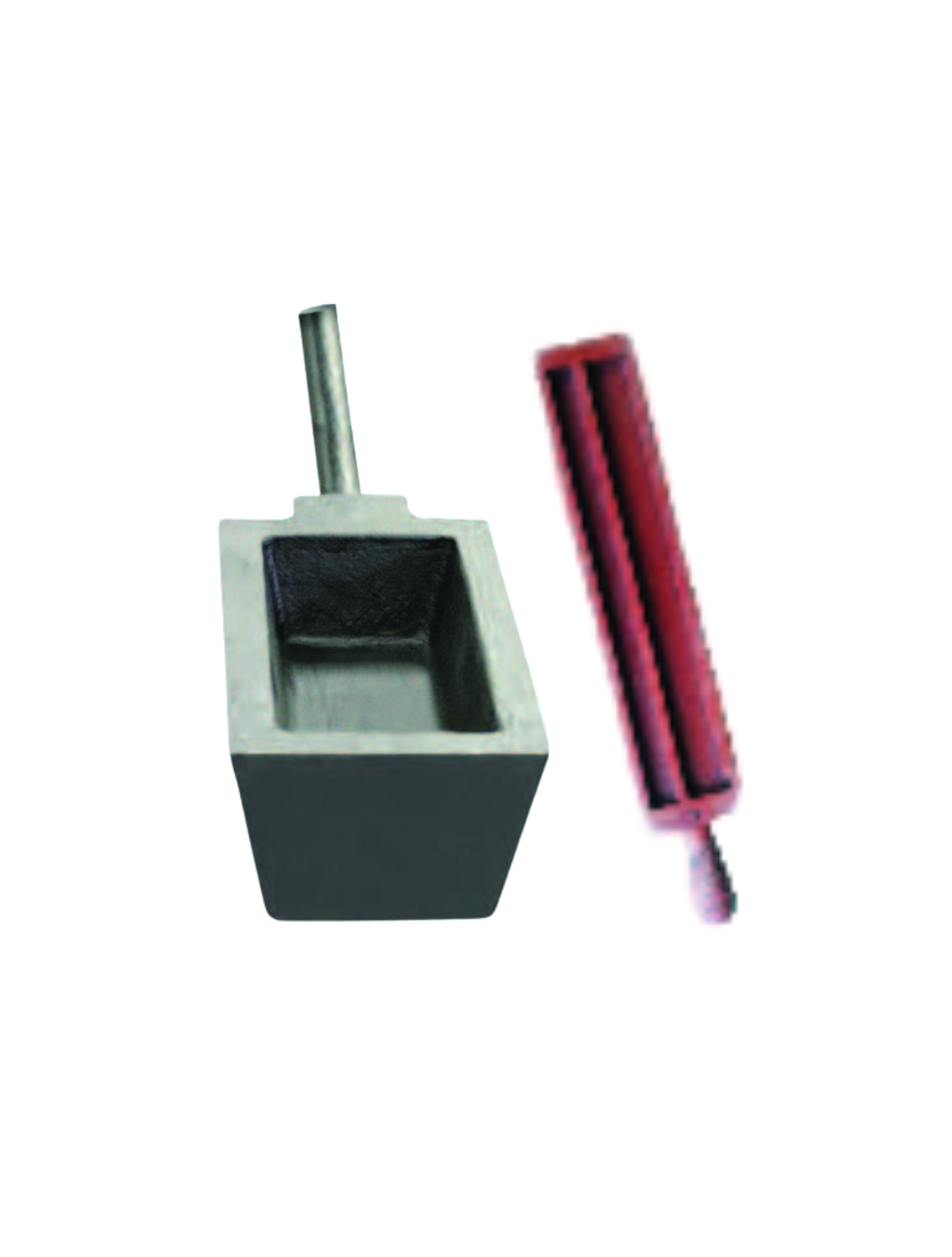

Graphite Stirrer Rods

Available sizes: [Diameter x Length]

- 10x300mm

- 12x300mm

- 16x300mm

- 20x500mm

- 25x500mm

- Custom sizes

Interested in this product? Chat with our team on WhatsApp:

Description

High-Performance Mixing Tool for Molten Metal in Crucibles

The Mechelec’s Graphite Rod Stirrers is a vital tool for refining, alloying, and mixing molten metals such as gold, silver, copper, and other non-ferrous materials during high-temperature operations. Specifically designed for use inside graphite or ceramic crucibles, this stirring rod ensures even distribution of heat, flux, and metal additives throughout the melt.

Constructed from high-purity, fine-grain graphite, the rod offers exceptional resistance to thermal shock and chemical corrosion, making it an ideal choice for continuous use in metal refining and casting environments. Unlike metal rods, graphite does not spark or introduce contamination, maintaining the integrity and purity of your molten metals.

Available sizes: [Diameter x Length]

- 10x300mm

- 12x300mm

- 16x300mm

- 20x500mm

- 25x500mm

- Custom sizes

Key Features of the Graphite Stirrer Rods for Crucible Mixing

-

High Thermal Resistance: Performs reliably in temperatures exceeding 1600°C without structural degradation.

-

Non-Reactive Material: Does not contaminate gold, silver, or copper melts—perfect for precious metal refining.

-

Smooth Stirring Performance: The cylindrical shape and polished finish allow controlled, consistent stirring.

-

Corrosion & Flux Resistant: Withstands exposure to most fluxes and alloying agents.

-

Safe to Use: Lightweight and compatible with rod holders for safe distance handling over hot crucibles.

- Various sizes: Stirrer rods are available in different sizes according to your specific needs. We offer standard and custom sizes upon request.

Applications of Mechelec Graphite Stirring Rods in Gold Refining

-

Mixing molten gold and silver in refining crucibles

-

Distributing flux evenly in bullion melting operations

-

Homogenizing molten alloys for jewelry casting

-

Improving metal flow and heat distribution in lab-scale melting units

-

Ideal for use in induction, electric, and traditional furnaces

Why Use a Graphite Stirrers for Molten Metal Instead of Metal Tools?

Using graphite rods for molten metal mixing ensures no unwanted reactions or sparks during the refining process. Unlike steel or iron rods, graphite maintains chemical stability and offers smooth movement through dense, high-temperature melts—making it the preferred choice for assay labs, metal recovery units, and jewelry manufacturers.

Order High-Quality Graphite Stirrer Rods from Mechelec

Mechelec offers premium-grade graphite stirring rods in various lengths and diameters. Whether you’re working in a gold refinery, jewelry workshop, or lab setting, our rods ensure clean mixing, better metal quality, and operational safety.

👉 Contact us today for custom sizes, bulk order pricing, or technical assistance.

Interested in this product? Chat with our team on WhatsApp:

FAQ’s

Q1: What is a graphite stirrer rod used for?

A: It’s used for stirring and mixing molten metals like gold and silver in crucibles to ensure uniform melting and temperature distribution.

Q2: Can this rod be reused?

A: Yes, Mechelec graphite rods are durable and reusable. However, they should be inspected regularly for signs of wear or erosion.

Q3: Is graphite safe for precious metals?

A: Absolutely. High-purity graphite is non-reactive and won’t contaminate gold, silver, or other molten metals.

Q4: What sizes are available?

A: We offer standard and custom sizes upon request. Contact us for availability or bulk customization options.