Gold melting is a precise and essential process in refining, casting, and manufacturing jewellery or electronic components. Whether you’re a hobbyist or a professional in metallurgy, understanding the science behind melting gold and selecting the right furnace and crucible can significantly improve your results. In this article, we’ll explore the key factors to consider when melting gold and how to choose the best furnace and crucible for the job.

Why Is Gold Melting Important?

Gold has a high melting point (around 1,064°C or 1,947°F), which means that controlling the temperature and using the correct equipment is crucial for achieving a smooth and efficient melt. Melting gold is typically done for:

- Refining: Purifying gold to remove impurities.

- Casting: Creating gold bars, coins, or jewelry.

- Recycling: Recovering gold from scrap materials.

The Science of Melting Gold

Before diving into the equipment, it’s important to understand the basic principles of melting gold.

- Thermal Conductivity: Gold has excellent thermal conductivity, meaning it heats evenly and quickly. This property makes it efficient to melt, but also requires a furnace capable of providing consistent heat.

- Melting Point and Temperature Control: The goal when melting gold is to reach its melting point without exceeding it too much, as this could cause oxidation or damage to the gold. Gold is a stable metal, but extreme temperatures can alter its structure and appearance.

- Heat Transfer: When melting gold, heat is transferred from the furnace to the crucible, which then heats the gold. The crucible material plays an important role in this process because it needs to withstand the high temperatures without reacting with the gold.

Choosing the Right Furnace for Gold Melting

There are several types of furnaces used for melting gold, each with its advantages and limitations. The two main categories are induction furnaces and traditional furnaces.

1. Induction Furnaces

Induction furnaces are highly efficient and precise, making them ideal for melting precious metals like gold. They use electromagnetic fields to heat the crucible directly, eliminating the need for direct flame or heating elements.

Advantages:

- Precise temperature control: Offers a high level of accuracy in melting temperatures.

- Faster melting: Heats the gold quickly and uniformly.

- Energy efficiency: Uses less energy than other methods.

Disadvantages:

- Cost: Induction furnaces tend to be more expensive than traditional furnaces.

- Complexity: Requires proper installation and understanding of operation.

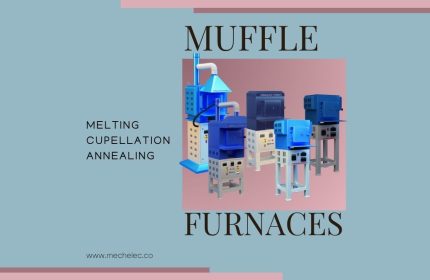

2. Traditional Furnaces (Electric and Gas)

Traditional furnaces use either electric heating elements or gas flames to melt gold. These are more common in small-scale or hobbyist settings.

Electric furnaces: Use electric resistance elements to generate heat. They are reliable and easy to use, but may take longer to reach the desired temperature.

Gas furnaces: Use a fuel source (e.g., propane or natural gas) to generate a direct flame. These furnaces heat up quickly but can be harder to control accurately.

- Advantages:

- Lower initial cost: Easier to find and generally more affordable.

- Simplicity: Simple to operate and doesn’t require specialized knowledge.

- Disadvantages:

- Less precise: Temperature control can be more challenging compared to induction furnaces.

- Higher energy consumption: May consume more power or fuel for extended heating.

Choosing the Right Crucible for Gold Melting

The crucible is just as important as the furnace when it comes to melting gold. The crucible should be capable of withstanding the high temperatures needed to melt gold and should not react with it.

Crucible Materials:

The material of the crucible must be chosen based on the melting process, the type of gold, and the desired outcome. Here are the most common materials used for gold crucibles:

Graphite Crucibles

- Excellent thermal conductivity for quick and uniform heating.

- Ideal for melting gold, silver, copper, and alloys.

- Durable and resistant to cracking under repeated high temperatures.

Clay-Graphite Crucibles

- A blend of clay and graphite for added strength and resistance.

- Suitable for both induction and gas furnaces.

- Long-lasting, with minimal erosion during repeated melting cycles.

Silicon Carbide Crucibles

- Highly resistant to thermal shock and extreme furnace conditions.

- Provide efficient energy transfer, making melting faster and more economical.

- Best for large-scale industrial applications where performance and durability are critical.

Induction Crucibles

- Specially designed for induction melting furnaces.

- Made to withstand rapid heating and cooling cycles.

- Ensure maximum metal purity by preventing contamination.

- Available in various sizes and shapes to match different induction systems.

How to Properly Use a Furnace and Crucible for Gold Melting

Once you’ve chosen the right furnace and crucible, here’s how to ensure the best results:

- Preheat the Crucible: Always preheat the crucible before placing gold into it. This prevents thermal shock, which can crack or damage the crucible.

- Use a Clean Crucible: Make sure the crucible is clean and free from debris. Any contamination can affect the purity of your melted gold.

- Monitor the Temperature: Use a high-quality thermocouple to monitor the temperature inside the furnace. This ensures that you don’t exceed the optimal melting point for gold (around 1,064°C or 1,947°F).

- Melting Process: Once the furnace reaches the desired temperature, carefully place your gold into the crucible. Keep an eye on the process, and avoid overloading the crucible.

- Safety Precautions: Always use appropriate personal protective equipment (PPE), such as heat-resistant gloves, goggles, and protective clothing, when handling hot materials.

Choosing the right furnace and crucible for melting gold is crucial for efficiency, safety, and achieving the desired results. Whether you opt for an induction furnace or a traditional furnace, paired with the right crucible material, understanding the science behind the process can ensure your gold is melted and refined to perfection. Proper equipment and techniques will help you avoid common pitfalls, like contamination or uneven heating, and lead to a smoother, more controlled melting experience.

By selecting the correct equipment and following best practices, you’ll be on your way to achieving high-quality gold melts every time.

If you’re looking for top-of-the-line gold melting furnaces and crucibles, check out our range of products designed for both professionals and hobbyists alike. Explore Our Products.