When it comes to testing gold purity, fire assay remains the most trusted and accurate method in the world. Laboratories have relied on this technique for centuries because it delivers precise, repeatable results even in modern times.

However, the success of fire assay depends not only on the method but also on the materials used. Among them, Lead foil plays a surprisingly vital role. Although it looks simple, this thin metal sheet is the foundation of accurate gold and precious metal testing. It collects valuable metals like gold and silver from the sample during melting, ensuring nothing precious is lost.

This article explains why lead foil is essential in the fire assay process, how it works, and why laboratories depend on high-purity foil to achieve reliable results.

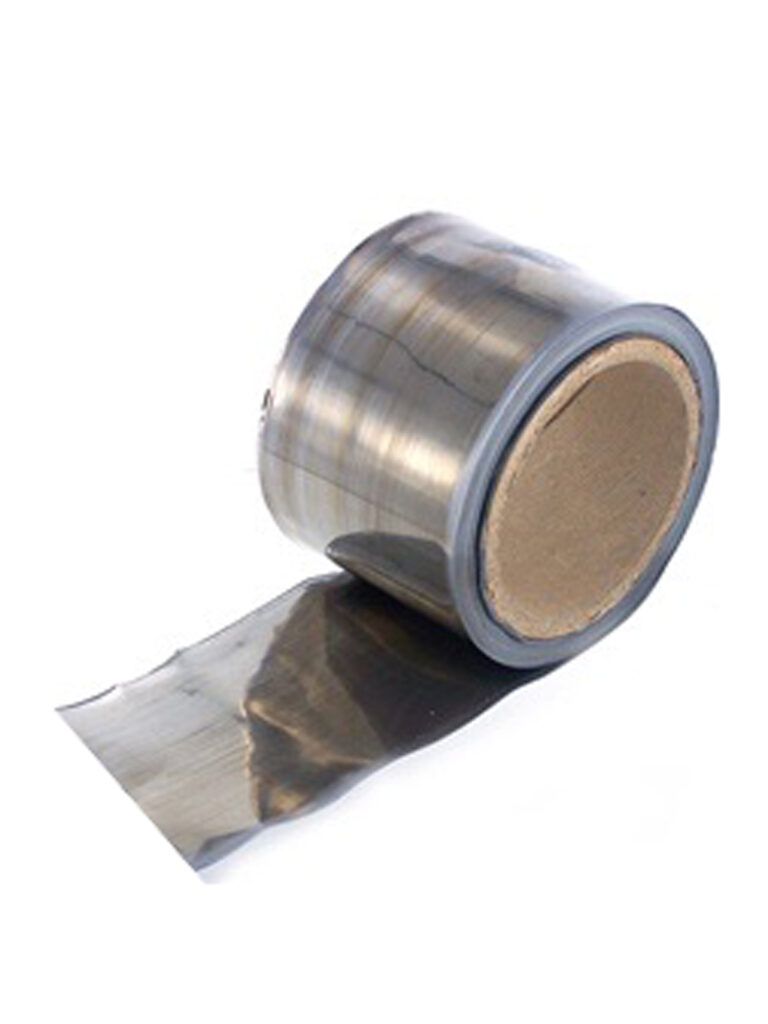

What Is Lead Foil?

Lead foil is a thin, flexible sheet made from high-purity lead. It is soft, malleable, and easy to shape, which makes it ideal for laboratory use. In fire assay, its purity and consistency are crucial because even small impurities can change how metals react and separate.

During the fusion stage of fire assay, the operator adds lead foil to the sample along with fluxes and other reagents. As the mixture melts under high heat, the lead acts as a collector metal, combining with unwanted materials like oxides and other impurities. This reaction separates valuable metals from precious metals such as gold, silver, and platinum, preparing the sample for precise measurement.

In simple terms, lead foil ensures that every trace of precious metal is captured for accurate analysis.

Role of Lead Foil in the Fire Assay Process

Lead foil performs several critical functions during the assay. When heated with fluxes and the sample, it melts, and it helps separate base impurities into a slag layer.

As the process continues, the molten lead interacts with fluxing agents such as borax and soda ash. This combination cleans the sample by removing contaminants.

In the cupellation stage, lead oxidises to litharge (lead oxide). What remains is a small metallic bead made up of the collected precious metals. Analysts then weigh and test this bead to determine the exact gold or silver content.

Without lead foil, this clean and accurate separation would not be possible. It is the key reason fire assay continues to be the most dependable method for gold testing worldwide.

Why Lead Foil Is Essential

The quality of lead foil directly affects the success of a fire assay. Although it may seem like a basic material, its performance ensures accuracy and repeatability.

- Accurate recovery: Lead foil collects every particle of gold, silver, and other noble metals during fusion. This complete recovery is what makes the results dependable.

- Clean separation: Lead naturally separates precious metals from unwanted base metals, creating a pure final bead ready for testing.

- Consistent melting: High-purity lead foil melts evenly and reacts smoothly with fluxes. Consistency in melting leads to reliable results across multiple tests.

- Precision and reproducibility: Quality lead foil eliminates variation. It allows laboratories to reproduce accurate outcomes every time they run an assay.

In short, lead foil turns the science of fire assay into a dependable, precise process.

Quality Matters: Importance of High-Purity Lead Foil

The purity of lead foil can make or break the accuracy of a gold assay. Even minor contamination can affect how metals separate or react, leading to incorrect results. Laboratories that value precision always choose high-purity lead foil.

When selecting lead foil, consider the following:

- Purity level: Choose foil with at least 99.9% purity or preferably 99.99% purity available at Mechelec. The higher the purity, the cleaner and more accurate your results will be.

- Thickness and uniformity: Even thickness ensures predictable melting and collection. Uneven foil may cause inconsistent results.

- Physical consistency: Quality foil should feel smooth, flexible, and easy to handle. It should wrap around samples without tearing.

By prioritising quality, laboratories can maintain reliable and repeatable gold assay results. Mechelec supplies high-purity lead foil made for accuracy and performance in demanding laboratory conditions.

Safe Handling and Environmental Considerations

Lead foil is essential, but it must be handled responsibly. Lead is a heavy metal, and improper handling can pose health and environmental risks.

- Wear gloves, masks, and lab coats when working with lead foil.

- Avoid direct skin contact, and do not eat or drink in assay areas.

- Ensure good ventilation near furnaces, especially during cupellation when lead oxide fumes may form.

- Dispose of lead residues and cupel waste safely.

- Always follow local hazardous waste rules and recycle used materials through approved facilities whenever possible.

Responsible handling protects both laboratory staff and the environment.

Conclusion

Throughout the fire assay process, lead foil plays an irreplaceable role in ensuring accuracy, purity, and reliability. It collects precious metals, enables clean separation, and supports the precision that laboratories depend on.

For consistent and trustworthy gold testing, high-purity lead foil is essential. Mechelec provides a complete range of high-quality assay materials, including lead foil, cupels, cupellation furnaces, ball pliers, and cornet hammers with an anvil, designed to help laboratories achieve accurate results every time.

By choosing the right materials and following best practices, you can ensure dependable fire assay performance and uphold the highest standards in gold testing.