Cupellation is a process of refining precious metals like gold and silver. It is mainly employed in assay labs and goldsmithing. A furnace with heating materials is used in the process to extract the impurities from the metal. Knowing how cupellation works is and should be the primary thing for workers in the refining industry. Here, we explain to you the various stages in the process, the part the cupels play, and why it is so vital to refine with precision if you attempt to be successful.

What Is Cupellation?

Precious metals are separated from base metals, mostly lead, through the fire assaying method called the cupellation process. Even though the method has been practised for a long time, it is still a very reliable means of gold refining and is widely used. The process is actually about taking a tiny piece of a metal (usually an alloy) and putting it in a hot furnace. The base metals get oxidised and amalgamate with a porous material called a cupel, while the precious metals, e.g. gold and silver, are left behind.

The previous sentence introduces the cupellation furnace process as a specialised machine designed for this purpose. Nevertheless, the term “understanding cupellation” in the question means the chemical and physical events taking place inside the furnace.

How Does the Cupellation Process Work?

The cupellation process can be broken down into several key steps. Let’s explore each one:

1. Preparation of the Sample

The metal sample, which is usually a mixture of noble and base metals like lead, is initially weighed and measured. The idea is to get a little sample that is filled with enough precious metal to provide an accurate reading.

2. Placing the Sample in the Cupel

Once the sample is prepared, it is positioned in a cupel. The cupel is a little, breathable crucible made from bone ash or a material like clay, meant to absorb the base materials as they undergo the process of being oxidised.

3. Heating in the Furnace

The cupel containing the sample is placed in a cupellation furnace and then heated to a very high temperature, above 1000°C. This very high temperature is needed for the base metals to oxidise and get absorbed by the cupel. Lead and some other base metals react with oxygen to create oxides, which are then absorbed by the cupel. High-quality cupels for cupellation are available at Mechelec.

4. Separation of Precious Metals

As the base metals are absorbed, the precious metals like gold and silver remain as a button of pure metal at the bottom of the cupel. This is the place where “buttoning” is derived from, which simply means that a bright, little metal bead is left after the operation is finished.

5. Final Bead Collection

After the oxidation is complete and the sample has cooled, the resulting bead of precious metal is extracted from the cupel. The weight of the remaining bead determines the purity of the precious metal and can then be assayed to identify the exact composition of gold or silver.

What Role Does the Cupel Play in the Cupellation Process?

The unsung hero of the cupellation procedure is the cupel. It is made in such a way that it could absorb the oxides created in the heating process, and yet the precious metals could be left in the form in which they were present. It is porous, hence it can absorb the lead and other impurities without interfering with the precious metals. Cupels vary in size and shape, and the cupel used may influence the effectiveness and precision of the process. Cupels are carefully chosen to maximise metal recovery, depending on the sample size and the type of furnace in operation.

Read more on cupels and their working here.

Why Is the Cupellation Process Important in Refining?

The cupellation process is essential in the precious metals industry for several reasons:

- High Precision: It allows for highly accurate separation of precious metals, which is critical in the gold and silver refining process.

- Cost-Effective: The process requires minimal equipment and can be scaled for both small-scale assays and large industrial operations.

- Purity: It results in high purity of precious metals, ensuring that gold, silver, and other valuable metals are recovered without contamination from base metals.

Cupellation Process vs. Cupellation Furnace: Key Differences

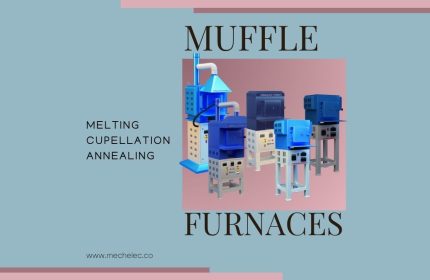

Whereas the cupellation procedure describes the procedure of refining, it is necessary to distinguish it from the cupellation furnace. A furnace is an essential instrument that is used in keeping up with the high temperatures needed in the process. It makes sure that the heat is distributed similarly and also provides an ideal condition in which oxidation of base metals takes place.

A cupellation furnace is usually well-controlled in temperature and has cupel holders. The modern furnaces are also fitted with other features such as gas regulation in flow, a feature that makes the oxidising conditions ideal to have a successful separation of metals. Use reliable cupellation furnaces for consistent refining accuracy.

Learn more about how cupellation furnaces work and their applications here.

Common Applications of Cupellation in the Industry

The cupellation process is widely used in the following areas:

- Assay Labs: To determine the purity of gold, silver, and other precious metals.

- Goldsmithing: For refining scrap gold or silver.

- Jewellery Making: To recover and refine precious metals from old jewellery.

- Mining: For evaluating the purity of ore and extracting valuable metals.

Key Takeaways

Cupellation is a traditional process which can be used to separate any precious metal and base metals. With adequate knowledge on how the process works as well as the utilisation of the right kind of equipment, including high-quality cupel and an effective cupellation furnace, a precious metal refinery can obtain high purity and efficiency. You may be interested in the gold refining business, an assay laboratory or a jewellery manufacturer, but in all cases, you need to learn and master the cupellation process to have a successful refining.

Read our full guide on fire assay equipment for a deeper understanding of lab essentials

Buy Cupellation Furnaces in the UAE from Mechelec

At Mechelec, we offer high-quality cupellation furnaces and cupels in the UAE that guarantee accurate and efficient metal separation. Contact us to learn more about how we can help optimise your refining process!