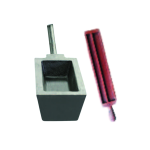

Tongs for Induction Crucibles

Available in a range of sizes to match your Induction crucible dimensions.

Interested in this product? Chat with our team on WhatsApp:

Description

Durable Tongs for Safe Handling of Induction Crucibles

Handle hot crucibles with confidence using Mechelec’s heavy-duty crucible tongs. Specifically designed for induction furnace applications, these tongs provide a secure, heat-resistant grip that makes pouring molten metals safer and more controlled. Whether you work in a gold refinery, casting unit, or melting lab, these tongs are an essential safety tool that delivers stability and precision every time.

Key Benefits of Our Induction Furnace Crucible Tongs

- Heat-Resistant and Heavy-Duty Build – Crafted for high-temperature operations in melting and refining processes.

- Secure Grip on Crucibles – Designed to fit snugly around crucibles used in induction furnaces.

- Available in Multiple Sizes – Choose from a range of sizes to match your Induction crucible dimensions.

- Safe and Ergonomic Handling – Designed to reduce hand strain and prevent accidental slips during pouring.

- Durable Steel Construction – Made from strong, corrosion-resistant materials for long-lasting performance.

- Precision-Made for Foundry Use – Reliable grip and balance for delicate or heavy metal pours.

Perfect for These Applications

• Gold, silver, and copper melting in induction furnaces

• Precious metal refining units

• Jewellery casting and fabrication workshops

• Laboratories and small-scale foundries

Engineered for Safety and Efficiency

At Mechelec, we understand the critical role of safety in high-heat environments. Our crucible tongs are manufactured to provide firm, slip-free control—even with glowing-hot crucibles. With proper care, they become a long-term asset to any melting setup.

Upgrade Your Foundry Tools with Trusted Equipment

Whether you’re upgrading your lab or setting up a new workshop, these induction crucible tongs ensure every pour is done safely and smoothly. Reliable, sturdy, and built for daily use—just what your furnace team needs.

👉 Available in multiple sizes for different crucible types. Contact us for sizing help or bulk order support.

Interested in this product? Chat with our team on WhatsApp: