Accurate temperature measurement is the foundation of every successful melting and refining process. In gold and silver melting, even a few degrees of variation can change purity levels and affect the final results. That’s where thermocouples for high temperature furnaces come in — delivering precise readings inside extreme furnace environments.

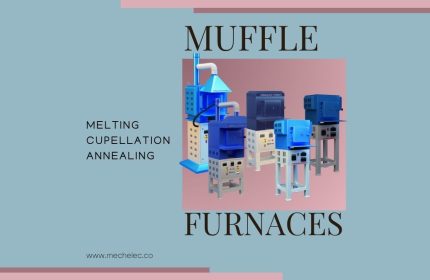

At Mechelec, we supply a complete range of thermocouples designed for fire assay, melting, and industrial furnaces. Each probe is engineered to maintain stability and reliability, even under continuous exposure to high heat. Whether you’re operating a gold melting furnace, a cupellation furnace, or an annealing system, the right thermocouple ensures consistent temperature control and improved productivity.

What Is a Thermocouple and How Does It Work?

A thermocouple is a temperature sensor made of two dissimilar metals joined at one end. When heated, it produces a voltage that corresponds to the temperature difference between the junctions — a principle known as the Seebeck effect.

Because of their durability and quick response, thermocouples are widely used across laboratories and refineries. They’re essential components in fire assay equipment, where accuracy determines gold or silver purity readings.

For more insight into key lab tools, read our guide: Fire Assay Equipment Explained: A Practical Guide for Labs & Refineries.

Why High-Temperature Thermocouples Matter

Standard temperature sensors fail beyond 1000 °C. High-temperature thermocouples, however, can withstand up to 1700 °C, making them indispensable in fire assay, metallurgical, and melting applications.

Their accuracy ensures:

- Safe and controlled furnace operations

- Protection for crucibles and SiC muffles from overheating

- Consistent, repeatable melting results

You can explore our complete selection of Heavy Duty Thermocouples and Precision Temperature Sensors designed for both laboratory and industrial applications.

How to Choose the Right Thermocouple for Your Furnace

When you select a thermocouple for gold melting, assay testing, or metal refining, keep these factors in mind:

- Maximum Operating Temperature – Pick a thermocouple rated higher than your furnace’s top temperature.

- Atmosphere Compatibility – Use protective sheaths for oxidizing or reducing environments.

- Accuracy and Response Time – Thin tips provide faster readings; thicker ones offer longer life.

- Mounting and Calibration – Position sensors near the heat zone but away from door openings.

- Maintenance Cycle – Replace probes that show corrosion or drift to maintain consistent accuracy.

For more on furnace heat control, read our blog: Gold Melting Furnaces: A Complete Buying Guide.

Common Mistakes to Avoid

Avoiding these errors will help improve reliability and extend your thermocouple’s life:

- Choosing the wrong thermocouple type for the temperature range

- Ignoring sheath protection in corrosive conditions

- Incorrect wiring or polarity, leading to false readings

- Skipping calibration, which causes drift in assay accuracy

Each mistake can lead to inaccurate purity results and unplanned furnace downtime.

📘 To learn how proper heat management supports refining, read: Graphite Crucibles – The Trusted Choice for Gold and Silver Melting.

Frequently Asked Questions (FAQ)

A: Replace them every 6–12 months, depending on operating intensity and environmental conditions.

A: It’s not recommended. Each furnace should have a dedicated probe calibrated for that unit.

A: Check for loose connections, oxidation, or damaged insulation. Regular calibration minimizes drift.

Buy Heavy Duty Thermocouples at Mechelec

Thermocouples for high temperature furnaces may be small components, but their role is critical. They ensure precision, safety, and consistency in every melting or refining process. Whether you operate a fire assay lab or an industrial furnace, choosing the right thermocouple is key to performance accuracy.

Explore Mechelec’s complete range of Furnace Thermocouples – built for endurance, precision, and long-lasting reliability.

For related topics, check out:

- Cupels in Fire Assay: What It Is, How It Works & Why It Matters

- Understanding Cupellation Furnace and Its Applications

- Fire Assay Equipment Explained: A Practical Guide for Labs & Refineries