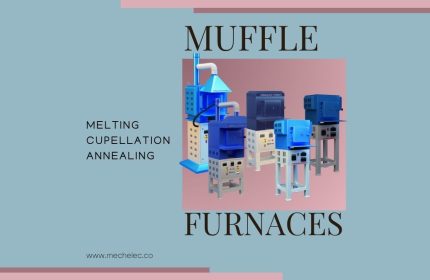

Cupellation helps extract precious metals like gold and silver from impure metals such as lead. In this process, technicians heat the impure metal to a high temperature and oxidise it to remove impurities. They carry out this process in a cupellation furnace, which is specially designed for efficient and accurate metal separation.

In this blog post, we’ll explore the Cupellation Furnace and its Applications in precious metal refining.

What is a Cupellation Furnace?

A cupellation furnace plays a key role in extracting precious metals from impure metals during the cupellation process. It features a refractory-lined chamber that heats to extremely high temperatures, allowing impurities to oxidise and separate from metals like gold and silver.

How does a Cupellation Furnace work?

In the cupellation process, technicians melt impure metal in a cupellation furnace at high temperatures, typically between 950–1050°C. As the metal melts, air inside the furnace oxidises it, causing impurities to react and form slag that rises to the surface. The precious metal, such as gold or silver, remains as a small bead on a bone ash or magnesite cupel. After the process, they remove the cupel from the furnace and let it cool. Once cooled, they weigh and analyse the metal bead to determine its purity.

Application of this Assay Furnace

Refiners commonly use cupellation furnaces to extract and purify precious metals, especially gold and silver. These furnaces also help analyse trace amounts of precious metals in ores, alloys, bullion, and coins. The cupellation process plays a key role in determining the exact gold and silver content in various materials.

The cupellation furnace is an essential tool in both refining and analytical processes. Its ability to separate and purify precious metals makes it valuable to industries such as jewellery, electronics, and mining.

At Mechelec, we understand the applications of Cupellation Furnaces and thus provide high-quality Cupellation Furnaces built for reliable and efficient performance. Whether you’re refining gold, silver, or other precious metals, our equipment ensures accuracy and durability.

Understand the step-by-step cupellation method for refining gold and silver

Contact us today to learn more about our products and discover how we can support your refining needs.